Resources

Choosing the right hardwood floor for your home or business is a matter of personal taste. Trust your instincts as you consider the hardwood features that will match your decorating style. When looking for a hardwood floor, consider these factors: wood species, solid or engineered construction, and the type of installation system.

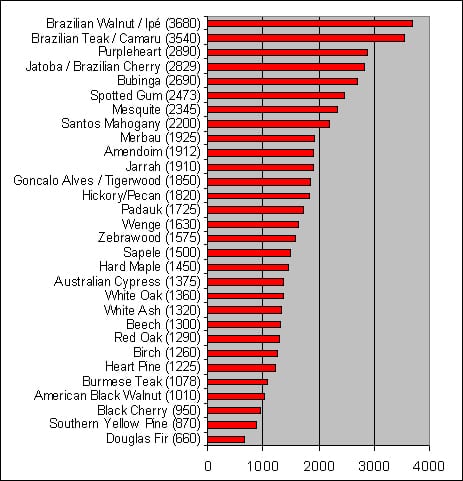

Hardness Scale

The Janka hardness is a test that measures the pound of force required to embed a .444-inch steel ball to half its depth into wood. This is the industry standard for measuring the ability of a wood species to withstand denting and normal wear. In addition it indicates the required effort it will take to saw or nail a certain wood species.

The Janka hardness is a test that measures the pound of force required to embed a .444-inch steel ball to half its depth into wood. This is the industry standard for measuring the ability of a wood species to withstand denting and normal wear. In addition it indicates the required effort it will take to saw or nail a certain wood species.

Please note that the higher the number the harder the species. Also this is a partial list of wood species.

Source: The hardness ratings for most species were taken from the U.S Department of Agriculture, Forest Service, Forest Product Laboratory, and the Center for Wood Anatomy Research.

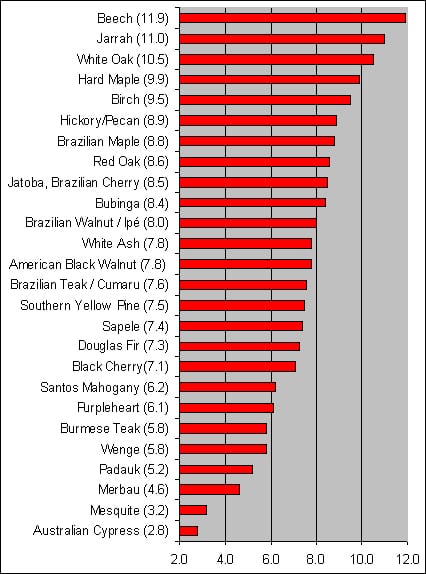

Dimensional Stability

In an effort to compare stability between species, the numeric values in the chart below represent the percentage of tangential shrinkage from green to overdry moisture content. Tangential change values normally will reflect changes in plainsawn wood. Quartersawn wood usually will be more dimensionally stable than plainsawn. Actual percentage change on completed job sites will be significantly less as proximity from board to board will restrain movement. Note this means the higher the percentage the more unstable the wood.

Also this is a partial list of some of the wood flooring species we offer.

Source: The Stability ratings were taken from the U.S. Department of Agriculture, Forest Service, Forest Products Laboratory and the Center for Wood Anatomy.

Specificiations

We can make or source virtually any flooring specification you may be interested in, if the wood is available! Let’s look at some of the key factors in selecting your floor:

Species:

There are literally thousands of species of wood that are made into flooring. Often your determination will be made for the species will be based on availability, the environment that the floor will be installed, and the aesthetic look you want to have. The chart we have for hardness and dimensional stability included in the website can help you with some of these choices. Of course, the internet is a great resource for the look of a floor but be sure you understand that pictures don’t always like the actual material. We can help with some of these issues with samples and other methods

FSC® (Trademark License Code: FSC-C007526) Certification available upon request:

Wood is a wonderful material: beautiful to look at, easy to work with, renewable, recyclable, carbon-efficient, low-energy and high-performance. FSC-certified flooring is a strong pillar for more sustainable timber management. Not only does FSC certification guarantee the use of environmentally-appropriate forest management practices in the production of wood, but it is also increasingly useful for companies participating in the green building industry, as well as helping ensure compliance with changing timber regulations and meeting increasing consumer demand for eco-friendly options. Top Grade Floors is an FSC Certified flooring reseller. If you are interested in this option please be sure to ask about it.

Wood is a wonderful material: beautiful to look at, easy to work with, renewable, recyclable, carbon-efficient, low-energy and high-performance. FSC-certified flooring is a strong pillar for more sustainable timber management. Not only does FSC certification guarantee the use of environmentally-appropriate forest management practices in the production of wood, but it is also increasingly useful for companies participating in the green building industry, as well as helping ensure compliance with changing timber regulations and meeting increasing consumer demand for eco-friendly options. Top Grade Floors is an FSC Certified flooring reseller. If you are interested in this option please be sure to ask about it.

Solid or Engineered:

There are many options and many reasons to use solid wood or to use engineered wood. We can help you work through some of these issues or your installer can help. If there are specifications for the material, we can make many floors in either application but not in all cases. Let us know what we can help with or further explain.

Thickness:

As thin as 5/16” in solid, but normally ¾” in solid or engineered and in some cases thicker in special applications. Wear layers on the engineered can vary as needed for your particular request. Again, the application or your environment will determine this factor.

Width:

Standard flooring widths generally range from 2” to 12” and sometimes wider, but there can be many other variations, we have made feature strip usually ¾” wide or wider, and currently inventory some feature strip, and have made flooring over 12” wide on many occasions. The reasons for the different widths are many. Sometimes for aesthetics a ¾” wide accent piece around the perimeter of a room can be beautiful. Wide and long plank flooring can have an amazing boldness to it. Of course, environment and budget and greatly affect what you finally decide to put into your space.

Lengths:

Parquet panels as short as 6 inches may be an option and flooring over 14 feet is possible. Industry standard flooring tends to range from one foot to seven-foot lengths, our standard lengths tend to be 2’ to 10’ but longer is possible. The average length of the flooring is a factor some don’t consider but a longer average length means fewer boards and a “cleaner” look. However as with other options a longer average length will add to the cost since fewer boards will make the grade for the final floor.

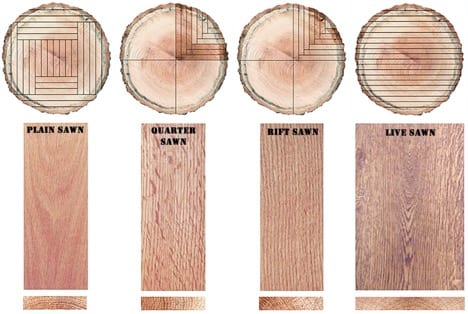

Plainsawn, Rift & Quartersawn, and Livesawn:

Plainsawn flooring is marked by any combination of any of the grain qualifications. It will exhibit the broad cathedral grain that is so evident in species like oak and pine.

Quartersawn flooring is denoted by pieces with the angle of the annual growth rings seen on the end of a cross section in the 45° to 90° range. Quartersawn flooring, especially in oak, will exhibit the medullary rays that are unique to this flooring cut. The advantage of this cut, besides the look, is there tends to be less tangential movement in the flooring since the distance between the growth rings is less than plainsawn.

Rift sawn in a cross section of flooring the growth rings will be between 30° to 60°. These are the clean lines that are sometimes present in wood flooring. The advantage of this cut, besides the look, is there tends to be less tangential movement in the flooring since the distance between the growth rings is less than plainsawn.

Rift & Quartered flooring is a mix of both rift sawn and Quartersawn pieces. The advantage of this cut, besides the look, is there tends to be less tangential movement in the flooring since the distance between the growth rings is less than plainsawn.

Livesawn flooring is a relatively new way of cutting logs for wood flooring. By slicing straight through the logs, the full effect of all the grain appearances listed above can be exhibited in one floor. The effect can be dramatic in the right environment.

Warranty

Top Grade Floors sources flooring and accessories from many manufacturers. Virtually all the warranties we offer would be from the specific manufacturer. For any flooring from Top Grade Floors you may always inquire for the exact warranty coverage for that product. With the millions of square feet of flooring sold since 1995 we have only experienced a handful of claims. Unfinished flooring should always be inspected carefully prior to installation to determine any moisture content or milling issues with the product. While this almost never occurs with our flooring, if it does, we will take the material back and replace it as needed BEFORE it is installed. This inspection, especially for moisture content, should be conducted immediately upon receipt to obtain, failure to do this could void any potential claim.

We want to ensure you have a product that you are confident in and that will last. That is how we do flooring!

Get in Touch

Don’t know what hardness you need? What does dimensional stability mean anyway? Ask away and let us help!